The Hong Kong Research Institute of Textiles and Apparel (HKRITA) has implemented a series of initiatives aimed at advancing sustainability in the fashion and textile sector, which has won three awards in the 2025 Just Style Excellence Awards in the categories of Environmental (Waste Reduction), Innovation (Waste Upcycling), and Research and Development (Functional Fabrics).

The Just Style Excellence Awards honour the most significant achievements and innovations in the apparel and textile industry. Powered by GlobalData’s business intelligence, the Awards recognise the people and companies leading change and shaping the future of the industry.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

HKRITA won the Environmental award for its comprehensive waste reduction initiatives, the Innovation award for pioneering the upcycling of beverage waste into new textile materials, and the Research and Development award for advancing the creation of sustainable, high-performance functional fabrics.

Environmental award for waste reduction initiatives

HKRITA’s approach to environmental responsibility is demonstrated through several integrated projects targeting waste reduction across the textile value chain. The Open Lab, launched in partnership with the H&M Foundation, serves as a 20,000-square-foot collaborative hub where industry stakeholders—including global fashion brands, textile manufacturers, NGOs, and research institutes—can engage in sustainable innovation. The facility features an artificial intelligence (AI)-driven garment sorting system that efficiently categorises textiles, the Green Machine 2.0, which can recycle up to one ton of PET-cotton blended textiles per day, and an industrial-scale upcycling line, transforming recovered materials into valuable new products. These capabilities enable the demonstration and scaling of practical recycling solutions, bridging the gap between laboratory research and commercial application. A key component of the Open Lab is its comprehensive digital database, which catalogues over 90 sustainable technologies developed by HKRITA. This resource supports knowledge sharing and accelerates the adoption of waste-reducing practices industry-wide. The Open Lab’s impact is further evidenced by its strong industry engagement, with over 1,500 visitors from diverse sectors and support from leading brands.

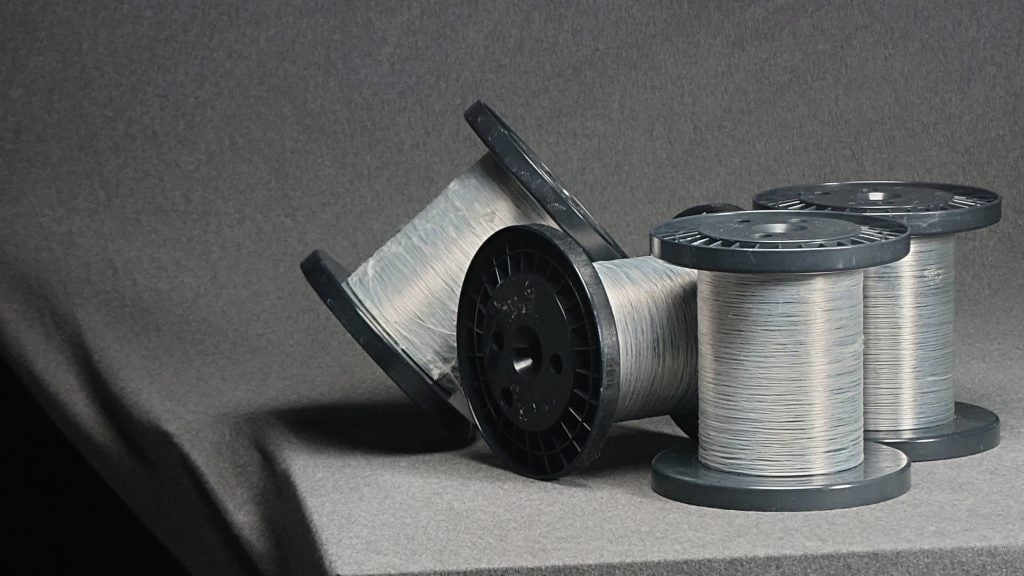

A significant advancement comes from HKRITA’s selective separation and recovery of nylon from textile waste, particularly from challenging blends like nylon and spandex. This process, conducted at room temperature and atmospheric pressure, using mild, low-cost solvents to isolate high-quality nylon polymers, which are then re-spun into fibres. The closed-loop system ensures over 99% solvent recovery, minimising environmental impact and reducing reliance on virgin materials. The regenerated nylon retains properties suitable for commercial spinning and textile applications, promoting the shift towards circularity in the fashion industry. HKRITA is actively collaborating with industry partners to scale this technology for broader adoption.

In addition to the Open Lab, HKRITA has developed a combinative indigo dye adsorption and regeneration system to address the environmental challenges posed by denim production. Indigo dye, which accounts for the majority of dyestuff used in denim, is a significant pollutant in textile wastewater. HKRITA’s system utilises metal-doped alumina as an adsorbent to efficiently remove indigo dye from wastewater. The adsorbent is regenerated using ozonated water, converting the dye into harmless substances and allowing for repeated use. This process achieves over 90% dye removal efficiency, reduces operational costs compared to traditional methods, and ensures that treated water meets stringent reuse standards for denim manufacturing. The technology has been recognised with a Gold Medal at the International Exhibition of Inventions of Geneva and is progressing towards pilot-scale deployment.

Innovation award for upcycling beverage waste into textiles

HKRITA’s innovation in waste upcycling is exemplified by its project to convert kombucha beverage waste into CelluLoop, bacterial cellulose fibres and CelluFilm, leather-like materials. This initiative addresses two major environmental concerns: the disposal of food and beverage waste and the resource intensity of traditional cellulose fibre and leather production. By sourcing bacterial cellulose from the fermentation byproduct of kombucha, HKRITA leverages a renewable and fast-growing raw material that requires significantly less water and fewer chemicals than cotton or wood-based alternatives.

The process involves fermenting tea with added sugar, harvesting the bacterial cellulose, and then using a novel, non-toxic aqueous solvent system to dissolve and regenerate the cellulose into fibres. Beyond fibres, the technology also enables the production of leather-like films from bacterial cellulose, offering a sustainable alternative to genuine and polyurethane (PU) artificial leather.

This approach provides new material options for the fashion and accessories market and reduces waste in leather production. The solvent system operates at room temperature and can be reused up to 98%, making the process both energy-efficient and environmentally friendly. The resulting bacterial cellulose fibres have demonstrated strong performance in laboratory tests for strength and elongation. Meanwhile, the BC leather-like films have also shown desirable performance under abrasion and flexing test.

The project has attracted collaboration from local F&B partners who supply beverage and fruit waste as feedstock, further integrating circular economy principles into the textile supply chain. The innovation has been showcased at major industry events and received a Gold Medal at the International Exhibition of Inventions of Geneva.

Research and Development award for functional and sustainable fabrics

HKRITA’s research and development efforts have resulted in the creation of eco-friendly, high-performance fabrics tailored for the growing sporty fashion and athleisure market. The project focuses on the use of eco-friendly and bio-based materials to develop yarns and fabrics with advanced functional properties. These materials are selected for their renewable origins and favourable environmental profiles.

The developed fabrics incorporate specific fibre distributions and structural designs to achieve multiple functions, such as one-way moisture transport and management, dimensional stability, and easy care. Notably, the fabrics have demonstrated superior performance in moisture management, surpassing comparable products in the market. The production process uses eco-friendly materials and is compatible with existing manufacturing infrastructure, facilitating industry adoption without the need for significant process changes.

The project has been presented at international exhibitions, including Intertextile Shenzhen and the International Exhibition of Inventions of Geneva, where it received a Silver Medal.

HKRITA’s ongoing research aligns with consumer demand for sustainable and high-performance apparel, supporting the industry’s transition towards environmentally responsible fashion choices.

Company Profile

Established in 2006, The Hong Kong Research Institute of Textiles and Apparel is funded by the Innovation and Technology Commission of the HKSAR Government.

HKRITA has achieved research deliverables over the years within its research clusters focusing on industry advantage, sustainability, and social benefits, through their in-house research teams, laboratories, and collaborations with industry partners and institutions.

HKRITA’s mission is to be a Hong Kong-based, world-renowned research institute for the textiles and clothing industry. Through concerted and focused R&D efforts, the institute aims to enhance the economic development of the HKSAR, mainland China, and overseas regions. Additionally, HKRITA facilitates technologies transfers of R&D results, in pursuance of continual development technologies to enhance the competitiveness of the industry both locally and internationally.

Contact Details

Website: www.hkrita.com

Email: info@hkrita.com

Tel: +852 26270180

Links