With rising production expenses, shifting consumer expectations, and increasing sustainability demands, brands must rethink how they operate to stay competitive. The new tariffs only added fuel to the fire, intensifying existing volatility and margin pressure for brands and manufacturers. At the same time, regulatory demands are becoming more complex and costly. Brands must now balance economic survival with environmental responsibility. Traditional cost-cutting is no longer sufficient—fashion companies must now embrace smarter, more strategic tools to stay competitive. Discover the solutions adopted by Chicago Protective Apparel, IKKS Group and Mango to face this challenging context, and the results they have achieved.

From cost-cutting to value creation

As Maximilien Abadie, Deputy CEO at Lectra explains, “For several years now, technology decisions have been framed as choices about how to improve individual tasks and increase output, instead of as opportunities to positively change strategic business outcomes – and this now has to change.”

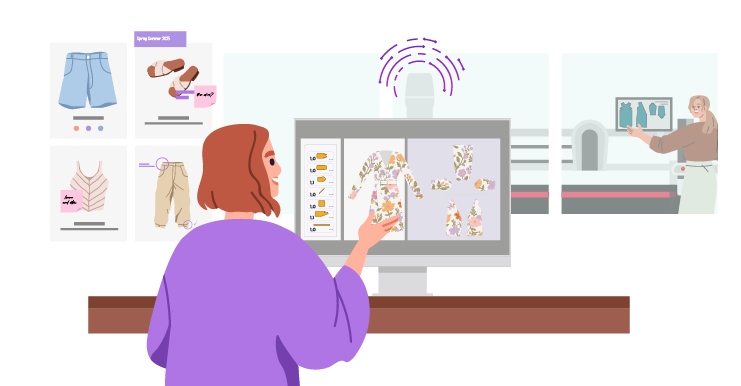

Lectra, a technology provider, offers a transformative approach that connects every stage of the fashion value chain—from design to production to marketing. Their solutions empower brands to move from reactive cost-cutting to proactive value creation. Lectra empowers brands, manufacturers, and retailers to create a truly connected ecosystem that enhances collaboration, transparency, and performance across the board. At the heart of this transition are the three strategic domains that form the backbone of the fashion value chain— Create, Manufacture, and Market—supported by seamless Collaboration and full Traceability. At the design stage, tools like Modaris and Gerber Accumark enable rapid prototyping and cost-effective patternmaking. In manufacturing, Valia Fashion Estimate optimizes fabric use and inventory, reducing waste and protecting margins. On the marketing front, Retviews, Launchmetrics, and Neteven provide real-time insights to boost sales and brand performance.

For instance, Chicago Protective Apparel (CPA), a leader in manufacturing protective garments for high-risk industries, turned to Lectra’s Vector Fashion iX6 automated cutting solution and Valia Fashion, their powerful cloud-based solution that delivers full visibility across operations. As a result, CPA has achieved notable operational improvements, including a 10% reduction in quality defects during the cutting process and an increase in overall nesting efficiency from 83% to 89%, resulting in a 6% gain in material efficiency. Additionally, lead times for material readiness have been shortened by five days.

“What I really liked about the Lectra side is that there was a team of people that worked with us to make sure the implementation would go smoothly,” said Keith Christiansen, President & GM at CPA. “Looking ahead, we’re confident that in the next five years we’ll grow our business fourfold – and Lectra will help us get there.”

Collaboration and transparency

Lectra also enhances collaboration through Kubix Link, a centralized solution that connects internal teams and external partners. After the success of implementing Retviews, the IKKS Group, a leading high-end fashion player, chose Kubix Link PLM solution to streamline collection management. “Kubix Link PLM is an innovative solution that makes collection management easier on a daily basis,” explains Mathias Perthuis, Purchasing Director at IKKS. “With tools such as Retviews and Kubix Link, we have optimized our processes while staying at the forefront of technology.”Retviews helps IKKS with real-time competitive analyses, thereby providing the brand with the agility it needs to fine-tune its strategic decisions. Now, with Kubix Link, the brand has seen a 5% improvement in delivery rates, a 10% reduction in air transport costs, and a satisfaction rate above 90% among internal teams. This solution has allowed the brand to improve coordination of its teams, streamline its processes and improve the traceability of its products, in line with its digital transformation and its commitment to more sustainable fashion.

Meanwhile, TextileGenesis ensures full supply chain traceability, helping brands meet compliance standards and build consumer trust. Mango, one of the leading international fashion groups, has joined forces with TextileGenesis, to trace their natural and animal fibers, synthetics, man-made cellulosic fibers and leather. Since the collaboration began, Mango has traced over 6,000 tons of sustainable fibers and more than 40 million finished product units across its value chain with TextileGenesis. The platform has also enabled Mango to engage over 1,000 supply chain actors in 23 countries, creating visibility well beyond certified fibers to include conventional materials, leather and footwear. This collaboration reinforces Mango’s commitment to building a transparent value chain and positions the company as a frontrunner in preparing for upcoming regulations and evolving consumer expectations worldwide.

The future of fashion profitability

In a disrupted market, agility, intelligence, and sustainability are key. Lectra’s integrated solutions help fashion brands build leaner, smarter, and more resilient operations. Discover how Lectra can help you rethink profitability and transform your operations.