COVER-SOMEONE Corp.’s ingredient brand CVSM won the Innovation, Research & Development, and Environmental awards in the 2025 Just Style Excellence Awards for taking a platform approach that pairs sustainable materials science with manufacturable design.

CVSM won the Innovation award in the Air Insulation category for introducing a controllable, air-based insulation platform that is manufacturable and scalable across categories. The company won the Research & Development award in the Photochromic Yarns category for advancing yarn-level photochromic technology and maintaining a clear, IP-backed pipeline from lab to market. It won the Environmental award in the Low-Impact Insulation category for replacing high-impact fills with air and enabling compact, modular designs that reduce logistics burdens and extend product life.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Innovation: CVSM Air Tech turns controllable air into a scalable insulation platform

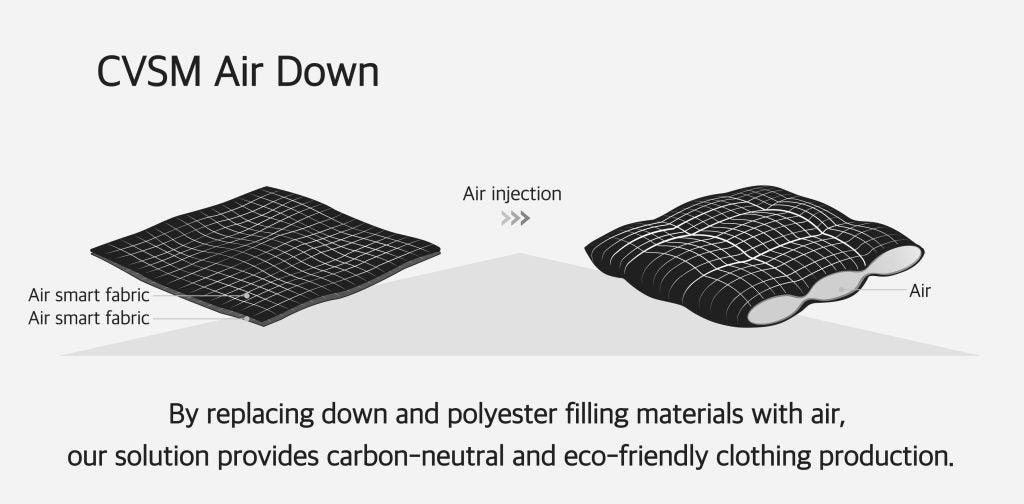

CVSM’s textile-based insulation system, Air Tech, replaces down or synthetic fill with air held inside flexible, welded chambers. It shifts insulation from bulk fill to engineered air, using high-frequency welding, a one-way injection valve, and ergonomic patterning to tune warmth, volume, and on-body mobility. This enables features conventional down or synthetic batting cannot offer: rapid inflation and deflation to match activity or weather, on-body adjustability for comfort, and modularity that lets brands build multiple silhouettes from common components. CVSM supplies the system as a complete ingredient kit—inflatable fabrics, valves, tubing, and optimized patterns—reducing integration time and minimizing retooling risk for factories.

The range of applications underscores scalability. In outerwear, modular vests and jackets use segmented air chambers to maintain natural range of motion while delivering consistent warmth, with a Korean accredited testing institution confirming thermal performance at 94.1% of conventional goose down. In lifestyle, the Pillowdy concept converts apparel into a neck pillow in about three seconds, meeting comfort needs without introducing foam fillers. In equipment, the Air Brief Bag inflates to protect contents during travel and doubles as a cushion, extending impact-dispersion benefits beyond apparel. In pet accessories, the Air Harness uses an ergonomic air module to reduce strain on the neck and chest during leash tension, applying the same air-control principles to animal use cases.

Market validation supports the innovation’s fit. Adoption by performance and fashion brands such as 3. PARAIDS, Michiko Koshino, Descente, and Post Archive Faction indicates the technology meets demanding standards for aesthetics, function, and reliability. Equally important, the progression from prototypes to repeatable kits demonstrates that Air Tech is manufacturable at scale. With the Smart Factory scheduled for completion in 2025, CVSM will bring air-tech package production in-house to further standardize quality and support larger rollouts. Overall, Air Tech combines originality—tuning insulation via air control—with the practical requirements product teams and factories need to deliver at spec and on schedule.

Environmental: Low-impact air insulation that cuts material footprints and logistics emissions

The environmental case for Air Tech begins upstream. By substituting animal-based down and petroleum-derived synthetic fills with air, the system reduces reliance on high-impact materials before garments enter cutting and sewing. Because air modules are compact and deflatable, finished goods and components can be transported and stored at lower volumes than pre-filled alternatives, helping to reduce logistics-related emissions in practical supply chain settings.

Environmental performance claims are supported by category-specific comparisons. In lifestyle travel, the Pillowdy product—serving as a substitute for polyurethane (memory foam) neck pillows—achieves a 2,188% reduction in carbon emissions compared with polyurethane-filled alternatives. In outerwear, a Korean accredited testing institution has validated that Air Tech delivers 94.1% of the thermal performance of conventional goose down in Air Jacket applications. These figures highlight that CVSM’s air-based solutions can offer meaningful environmental benefits while maintaining the performance consumers expect in each product category. Because CVSM delivers Air Tech as a ready-to-integrate kit that fits existing manufacturing workflows, the potential for scale extends across outerwear, accessories, and travel goods, broadening the scope of impact beyond a single product line.

R&D: Photochromic yarns with long-cycle durability and a clear path to market

CVSM’s R&D program is organized around two thrusts: continuous optimization of the air platform and development of next-generation smart textiles, notably Heated Tech and UV Color Change. The UV Color Change work is particularly notable because it embeds photochromic responsiveness at the yarn level rather than relying on coatings. That materials choice addresses two chronic obstacles in smart textiles: maintaining hand-feel and ensuring durability after repeated exposure and wear. Company testing indicates the yarns maintain functionality for more than 100,000 UV cycles, a durability level aligned with repeated real-world UV exposure.

The engineering approach is integrative. Textile construction, polymer selection, and product design are developed together, which is evident in the way Air Tech elements—such as the one-way injection system and modular chamber architecture—translate into a variety of product formats without compromising comfort or core function. Examples include the conversion mechanism in Pillowdy and the multiple Air Bag Kit variants that adapt to different silhouettes while preserving the same inflation and sealing logic. This system thinking shortens the distance from laboratory validation to manufacturable products and supports a consistent user experience across categories.

CVSM backs this pipeline with intellectual property and planned manufacturing capability. The company reports more than 200 IP rights across patents, designs, and trademarks in key markets, helping protect both the air-control architecture and the yarn-level smart functions. On the industrial side, bringing air-tech package manufacturing in-house in 2025 is designed to tighten quality control and improve cost competitiveness—two factors that often determine whether advanced textiles progress from niche runs to broader adoption. While Air Tech is already commercial, the R&D organization is structured to move Heated Tech and UV Color Change toward ingredient-brand status, leveraging the same kit-based transfer model that has reduced integration risk for partners.

“At CVSM, we strive to transform everyday life through sustainable innovation. By advancing eco-friendly textile technologies, we are redefining the possibilities within the fashion industry, delivering products that seamlessly combine design and functionality, and adding tangible value to our customers’ lifestyles. Moving forward, we are committed to leveraging our innovative material technologies to drive positive change across the industry and strengthen our position as a leading global fashion-tech company.”

– Lee Jae-ho, CEO, CVSM

Company Profile

CVSM is a South Korea–based fashion-tech materials brand that develops sustainable high-performance textiles using the properties of air, heat, and light, and is rapidly expanding its presence in the global fashion industry.

Since the founding of COVERSOMEONE in 2017, CVSM has introduced proprietary technologies such as Air Tech, Heated Tech, and Photochromic Yarns, creating new material categories beyond the limitations of traditional fills and functional textiles.

With a focus on in-house R&D, CVSM has collaborated with leading Korean brands including Post Archive Faction (PAF), Descente, K2, and Kolon Sports, establishing a strong domestic presence. The company has also expanded its global partnerships, working with 3.PARADIS in France, GAP in the United States, and ANA Airlines and FreshService in Japan, demonstrating technical credibility and international applicability. Recently, CVSM has begun a new project with the British brand Michiko Koshino, strengthening its influence in the European market.

CVSM’s Air Tech uses air as a structural material to overcome the limitations of down and synthetic fills, offering lightweight, adjustable, and sustainable solutions. Heated Tech and Photochromic Yarns provide additional performance and design capabilities, enabling global brands to develop new types of products.

With over 200 international intellectual property rights, CVSM has grown from a Korea-based technology brand into a next-generation ingredient brand operating across Asia, North America, and Europe. The company has obtained ISO 9001 (Quality Management System) & 14001 (Environmental Management System) certificates.

Contact Details

E-mail: sales@cvsm.kr

Links

Website: https://coversomeone.com/