Adopting new technologies has become critical in organisations across all industries to help improve process efficiency, effectiveness, and boost performance. Here are some with the potential to revolutionise key points of the apparel retail supply chain.

Organisations increasingly depend on information technology to manage and improve their systems, and ultimately survive against their competitors.

The importance of information has never been so prevalent in the retail supply chain, where it is crucial to monitoring and improving production efficiency, product design and quality management, and ultimately contributes to getting as close as possible to market expectations.

The textile and apparel industries, along with many other sectors, rely on technology in their supply chains to improve the accuracy and speed of information across all the different stages. From the sourcing of materials, to the manufacturing of products, all the way up to the point of consumption and delivery, technologies are set to see these stages become quicker, cheaper and more transparent.

Here are some of the key technologies that have the potential to revolutionise key points of the supply chain process:

Supply chain coordination

The performance of the apparel retail industry relies on the quick and smooth coordination between the supply chain, retailer and consumer. One of the most common ways this takes place is through vendor-managed inventory, which is where the manufacturer and retailer work as a single unit, with the former helping the latter replenish inventory when necessary. In addition, the communication between both manufacturer and retailer in the supply chain is critical in analysing sales performance etc.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataWhile this is currently in place across some of the clothing industry, there is still work to be done. Issues persist around the accuracy and sharing of data, and also on the communication between manufacturers and retailers.

The Internet of Things (IoT) is something that will improve this relationship between manufacturer and retailer, and as a result make supply chain coordination more effective. IoT is all about connecting devices over the internet, allowing for the interlinking of data and communication between us, our devices and applications. This piece of technology will ensure the most up-to-date and most accurate information is being exchanged between manufacturer and retailer, which will help reduce delays. IoT as a tool of advanced technology will also help reduce the issues around trust as it will improve the accuracy of the information shared.

This technology is expected to take off, with the World Economic Forum predicting that 1 trillion sensors will be connected to the internet by 2022. For supply chain managers and retailers, IoT will increase the visibility in all processes, draw attention to potential faults in each supply chain operation, and from this, enable ways to improve the systems process, accuracy and efficiency.

In addition to the IoT, ‘Big Data’ is also critical in revolutionising the apparel supply chain. Access to more data will increase visibility across the chain, dramatically improving business intelligence and communication.

The increased sharing of information made possible by these two technologies will also improve the communication between retailers and their customers, thus helping to reduce the number of customers lost. Not only this, but more information will enable an increased accuracy at forecasting markets, products and sales in the future, critical in the fashion industry. While this would be useful for both small and big companies, it would arguably be more beneficial for the latter who deal with significantly larger figures.

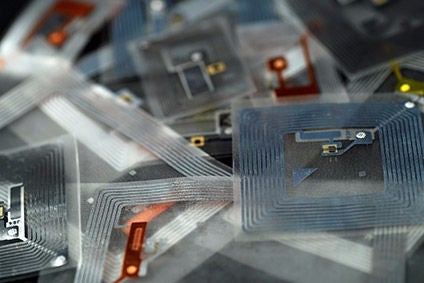

RFID

Radio Frequency Identification (RFID) is a hot topic in the retail supply chain, with fashion retail giants such as Marks & Spencer adopting this technology into their organisation. RFID is essentially an advanced automatic tracking system that can monitor inventory and record product movement, helping to reduce costs and increase the accuracy and control over the many different locations a product goes through before reaching the stores. While RFID is being implemented by big retailers, there is currently a debate on whether the technology is worth the cost to implement in smaller companies.

In addition, risk management is at the top of agendas for almost every CEO in fashion companies, due to the constantly changing market conditions, combined with the unstable prices of commodities such as cotton persisting. As companies are increasingly looking more into finance topics and the issues of risk, ‘Big Data’ and IoT should help to reduce this uneasiness and allow organisations to make better informed predictions and decisions about their markets.

Drones

Arguably one of the more exciting technologies to emerge is drones, which are set to be adopted across the apparel retail industry in the next 15 years. Consumer-goods giants Amazon and Walmart are one step ahead of everyone, already implementing them into their warehouses:

Amazon has Prime Air set up, which is a delivery system that uses drones to safely deliver packages to customers in under 30 minutes. For Amazon, this rapid parcel delivery will improve the safety of the delivery process and the overall efficiency. This is a perfect example of the extent the supply chain has on our lives. You won’t be waiting anxiously for the postman to arrive after a few days with drones in the skies.

Walmart is using drones at a different stage of the supply chain, implementing them to carry out a full warehouse inventory check. The result of this is a drastic improvement in time and accuracy, as previously this process could take up to a full month to complete when conducted by humans. With drones it can be achieved in a single day.

The use of drones by Amazon and Walmart will soon spread across the whole retail sector, with this flying technology helping track goods in the warehouse, and also delivering ordered commodities to consumers.

Combined, these technologies are set to transform the apparel retail industry entirely. From tracking the location of materials, to improving the communication between retailers and manufacturers, these innovations should enhance the efficiency, cost and effectiveness of the supply chain, improving overall performance as a result.

About the author: Technology and automations firm Vero Solutions, a subsidiary of Harland Simon, works to improve efficiency, profitability and safety in logistics and manufacturing environments by using a range of advanced location technologies to track people, assets and inventory. The company works with warehouse, manufacturing as well as other industrial and commercial businesses across the UK.