As environmental concerns gain traction, textile companies are under growing pressure to rethink how they use resources. Ekoten Tekstil (Ekoten) is one such company taking action, introducing a fresh approach to water management in textile manufacturing. Their clean-tech Wastewater Recovery System has earned them the Innovation award in the 2025 Just Style Excellence Awards in the Wastewater Recovery category.

The Just Style Excellence Awards, backed by GlobalData’s business intelligence, honor the companies making significant progress in the apparel and textiles industry. The independent recognition program recognizes the people and organizations actively shaping the industry’s future.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Ekoten stood out for raising the bar in water efficiency, environmental responsibility, and operational performance.

A new take on wastewater: Chemical-free and resource-smart

One of the most interesting aspects of Ekoten’s project is its chemical-free approach to treating wastewater. In textile dyeing, it’s common for factories to rely on chemicals to clean used water. Though effective, this method often leads to high freshwater use and can create environmental headaches due to chemical runoff.

Ekoten decided to do things differently. By teaming up with a biotechnology start-up, they developed a system that skips chemical purification altogether. Instead, they use a mix of advanced tools, which include an Energized Oxygen System (EOS), Membrane Bioreactor (MBR), several filtration stages, and a three-stage reverse osmosis (RO) process.

The results speak for themselves. During a 45-day pilot, the system treated and reused over 48,000 cubic meters of wastewater, which is enough to cover about two-thirds of the dyeing department’s daily needs. By 2024, recovery rates had climbed past 80%. Ekoten has its sights set on reaching 90% by the end of 2025. The recovered water goes straight back into production, which means less demand for fresh water and a more circular approach to water use. On top of that, this process helps keep pollutants like chemical oxygen demand (COD), biological oxygen demand (BOD), suspended solids, nitrogen, and oil-grease out of local waterways.

Smart technology and real-time oversight

Ekoten’s system is designed to be flexible, adjusting its capacity as needed. Real-time data collection and strict quality checks allow the team to fine-tune operations on the fly, ensuring both efficiency and consistent water quality.

Energy use hasn’t been overlooked either. By optimizing blower motors and energized oxygen systems, Ekoten has managed to reduce energy consumption to levels lower than Best Available Techniques (BAT) such as ZLD, a win for both the environment and the bottom line.

The multi-stage treatment process, which combines biological and membrane filtration, is scalable. This means the same approach can be used at other production sites if needed. To back up their claims, Ekoten had third-party organizations verify the system’s performance, submitting the results to the Scientific and Technological Research Council of Türkiye/Turkey (TÜBİTAK) MAM (Marmara Research Center). This independent validation adds credibility and transparency to the project.

Collaboration, sharing, and looking ahead

In its innovation journey, Ekoten partnered with a biotechnology start-up, which brought in new expertise and fresh ideas, helping to solve some of the trickier challenges in textile wastewater management. Ekoten has also been open about sharing what they’ve learned, through sustainability reports, industry events, and direct conversations with customers. Inside the company, staff training and awareness campaigns have helped make this project a core part of Ekoten’s sustainability culture.

The project lines up well with several United Nations Sustainable Development Goals (SDGs), including clean water and sanitation, industry innovation, responsible production, and climate action. By aiming for zero liquid discharge and a 90% recovery rate, Ekoten is showing a long-term commitment to environmental stewardship. Their adaptable system could serve as a blueprint for other water-intensive industries looking to close the loop on water use and move toward more sustainable manufacturing.

“At Ekoten, we have always drawn our strength from sustainability and innovation. This award stands as a powerful testament that our vision is not merely words, but a reality recognized on an international stage. For us, every achievement is not an endpoint, but a new beginning — a step forward on our continuous journey of progress. Every action we take today is an investment in a better tomorrow, adding lasting value to both people and the planet. We see sustainability not as a choice, but as the only way forward. That’s why Ekoten is not a company that waits for the future — we are the one working to build it with courage and innovation.”

– Gizem Calis, Operational Excellence Assistant General Manager at Ekoten

Company Profile

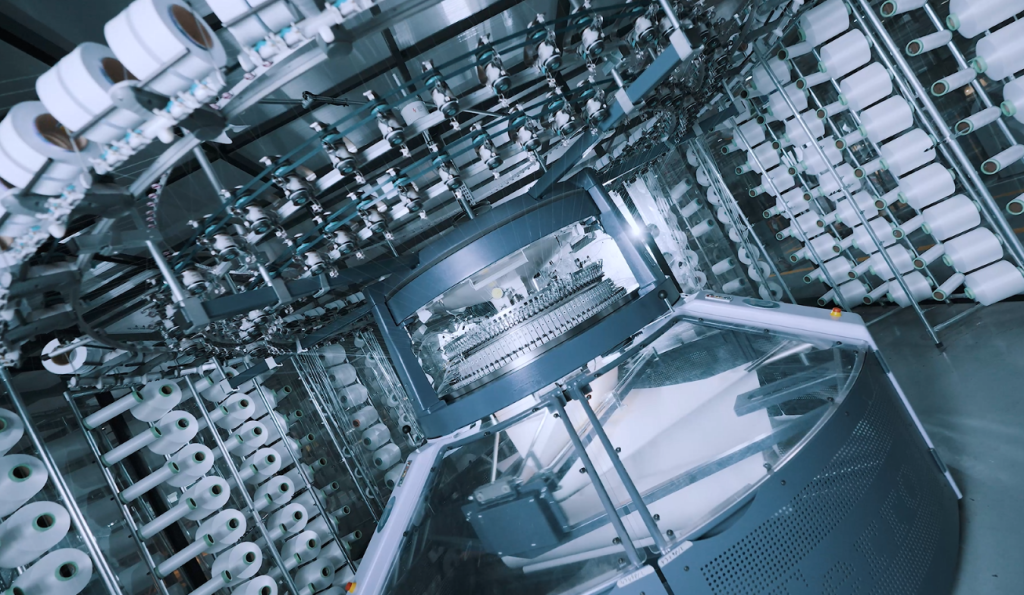

Ekoten is the largest knitted fabric manufacturer in Turkey and Europe, and Turkey’s leading exporter of circular knitted fabrics. With 235 state-of-the-art knitting machines, a daily production capacity of 40 tonnes, and a unique fabric library, Ekoten delivers high-performance, innovative, and functional fabrics to the fashion, medical, and activewear industries.

Powered by advanced dyeing technologies, automated systems, and certified R&D expertise, the company combines design and technology to create the fabrics of the future, today. With eco-friendly production facilities, wastewater recovery systems, and internationally recognized sustainability certifications, Ekoten leads the way in environmental responsibility and innovation — together for a better future.

Contact Details

Gizem Calis, Deputy General Manager

Links:

Website: https://www.ekoten.com.tr/