Yeşim Group received the Innovation award in the 2025 Just Style Excellence Awards for its integration of automated, artificial intelligence (AI)-powered inspection technology in circular knitting, which has transformed quality control and waste reduction in textile manufacturing. Developed in partnership with Smartex.AI, the initiative represents a notable development in textile manufacturing by addressing longstanding challenges in quality control, efficiency, and waste reduction.

The Just Style Excellence Awards honor the most significant achievements and innovations in the apparel and textile industry. Powered by GlobalData’s business intelligence, the Awards recognize the people and companies leading positive change and shaping the future of the industry.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Yeşim Group won the award for its pioneering approach that set a new standard for precision, efficiency, and sustainability in the industry.

Addressing traditional quality control challenges

The circular knitting process is a cornerstone of textile manufacturing, but it has historically relied on manual inspection methods that are both labour-intensive and prone to error. During the fabric production process, such as knitting, the fabric is produced inside the machine, after it reaches a certain amount, the fabric is removed from the machine in batches and undergoes a quality control inspection. As a result, defects are frequently detected only after significant lengths of fabric have been produced, leading to large volumes of material waste, costly rework, and production delays.

Late detection of defects also means that more raw materials such as yarn, dyes, and energy are consumed in producing goods that may ultimately be unusable or require extensive repair. This impacts profitability and undermines sustainability goals. The lack of a systematic, real-time solution for identifying and addressing recurring errors further compounds the problem, resulting in repeated production of faulty material and significant amounts of scrap. Operators, often working long shifts, may miss subtle defects or inconsistently grade fabric quality.

Recognizing these challenges, Yeşim Group sought to fundamentally transform its quality control approach. The company’s collaboration with Smartex.AI was aimed at introducing a system capable of real-time, highly accurate defect detection, reducing reliance on manual oversight, and shifting the focus from reactive correction to proactive prevention.

Real-time AI inspection and the “Golden Stop” mechanism

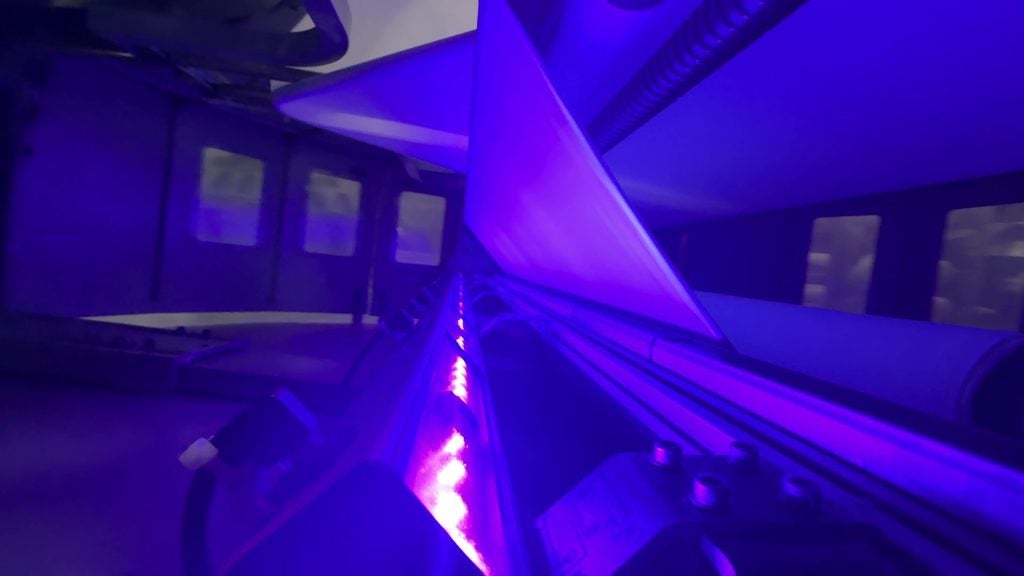

The Smartex AI system, integrated onto Yeşim’s circular knitting machines, leverages advanced optical sensors and machine learning algorithms to inspect fabric as it is produced. This non-contact, non-destructive method captures high-resolution images and identifies a range of defects, including horizontal and vertical lines, spotty holes, and oil marks, at the earliest possible stage. The system’s adaptive learning capabilities mean it can be retrained with new defect data and fabric types, ensuring ongoing effectiveness as production needs evolve.

A defining feature of Yeşim’s implementation is the co-developed “Golden Stop” mechanism. Unlike traditional alert systems that simply notify operators of defects, Golden Stop enforces immediate intervention when recurring critical errors are detected. If the system identifies the same critical defect within a defined threshold, it automatically halts the knitting machine. A password-protected screen then requires an authorized supervisor to investigate and resolve the root cause before production can resume. This enforced pause ensures that persistent issues are addressed at their source, preventing further waste and reinforcing a culture of operational discipline.

The system also provides comprehensive, actionable data on defect types, frequencies, and locations. This data empowers Yeşim’s teams to conduct precise root cause analysis, optimize machine settings, identify underperforming raw materials, and engage in proactive maintenance. By moving beyond simple defect detection to deliver quality intelligence, the Smartex AI system transforms quality assurance into a strategic driver of operational excellence.

Measurable impact and data-driven process optimization

The implementation of Smartex AI has delivered clear, quantifiable benefits for Yeşim Group. In Lycra jersey production, for example, machines equipped with Smartex achieve a remarkable reduction on nearly 70% in defects, significantly enhancing product quality. This improvement has a cascading positive effect, as the fewer defects also lead to increased efficiency and reduced waste during subsequent stages such as dyeing, finishing, cutting and garment production. The early and precise detection of issues—such as oil marks, which were resolved by changing the oil—has minimized the need for post-production correction and reduced material waste.

The system’s data analytics capabilities have enabled Yeşim’s R&D and production teams to monitor performance continuously, conduct root cause analysis, and implement targeted improvements. For instance, the identification of recurring defects has led to adjustments in machine settings and maintenance schedules, further enhancing efficiency and product quality. The ongoing collaboration with Smartex supports continuous improvement, with regular updates to AI models and the addition of new features based on evolving production requirements. By shifting quality assurance from a reactive necessity to a strategic function, Yeşim Group has achieved measurable gains in capacity, shortened lead times, and improved customer service. The integration of AI-driven inspection has also contributed to the company’s broader sustainability objectives by reducing raw material consumption and minimizing the environmental impact of defective production. These outcomes underscore the value of data-driven process optimization in modern textile manufacturing.

“On behalf of Yeşim Group, I would like to congratulate our entire knitting production team, our R&D colleagues, and our valued partner Smartex for this remarkable achievement. Winning the ‘Innovation’ category in the 2025 Just Style Excellence Awards with our AI-powered Intelligent Inspection and the co-developed ‘Golden Stop’ mechanism marks a proud milestone for us.“

– Selim Şankaya, Co-CEO of Yeşim Group

“This award is fully aligned with Yeşim Group’s corporate mission: ‘To create irreplaceable value through excellent customer service and sustainable growth, to protect the planet, and to be the core strategic manufacturing partner of the world’s leading brands with a People First approach.’ At every step, we remain committed to this mission. Today’s success reflects our dedication to continuously enhancing quality, investing in technologies that reduce waste, improve efficiency, and protect the environment.

At Yeşim, we see quality assurance not merely as a control process, but as a strategic force that moves our business forward. In our collaborations with global sportswear and premium brands, we consistently prioritize excellence and sustainability. This recognition not only confirms that we are on the right path, but also inspires us to aim even higher. This achievement is a strong reflection of Yeşim’s determined journey toward the future. I extend my heartfelt thanks to all colleagues who contributed with their efforts, vision, and dedication,” Şankaya added.

Company Profile

Rooted in 1956, Yeşim Group holds a leading position in the textile industry as a strategic and indispensable manufacturing partner for global brands. Headquartered in Bursa, Türkiye’s textile capital, Yeşim operates not only at its central production facility but also through contracted production across various cities in Türkiye, while managing its international operations in Egypt and Moldova. As one of the world’s prominent integrated facilities, Yeşim Group carries out all processes of the apparel industry in-house, from yarn to finished product.

With a daily capacity of 115 tons of knitting, 125 tons of dyeing, 100,000 meters of printing, 400,000 pieces of apparel, and 100,000 pieces of home textile products, Yeşim operates on a total area of 326,000 square meters in Bursa, of which 144,000 square meters is covered and 182,000 square meters is open space. This scale positions Yeşim among the largest companies in its region, acting as a key economic driver with its strong employment and export power.

Through its innovative corporate culture, Yeşim Group continuously renews itself, closely follows industry trends, and adapts proactively. Its R&D center—certified by the Ministry of Industry and Technology—has pioneered numerous breakthroughs in smart, organic, recycled, and innovative fabrics, reinforcing its leadership in textile innovation. Today, Yeşim Group continues its strategic partnerships with some of the world’s most renowned brands, including Nike, Under Armour, Zara, Bershka, Tommy Hilfiger, Lacoste, Calvin Klein, Polo Ralph Lauren, Aldi, Gerster, Schlafgut and Tchibo.

Links

Website: https://www.yesim.com