Researchers in Canada have joined hands with premium outdoor brand Arc’teryx to develop what they claim is one of the world’s first non-toxic oil and water-repellent performance textile finishes.

A team at the University of British Columbia’s Okanagan Campus have been working to develop a sustainable, non-toxic and high-performance water-repellent fabric, which they say has long been the holy grail of outdoor enthusiasts and clothing companies alike.

Outdoor fabrics are typically treated with perfluorinated compounds (PFCs) to repel oil and water. But according to Sadaf Shabanian, doctoral student at UBC Okanagan’s School of Engineering and study lead author, PFCs come with a number of problems.

“PFCs have long been the standard for stain repellents, from clothing to non-stick frying pans, but we know these chemicals have a detrimental impact on human health and the environment,” she explains. “They pose a persistent, long-term risk to health and the environment because they take hundreds of years to breakdown and linger both in the environment and our bodies.”

Mary Glasper, materials developer at Arc’teryx and collaborator on the project, adds these lasting impacts are one of the major motivations for clothing companies to seek out new methods to achieve the same or better repellent properties in their products.

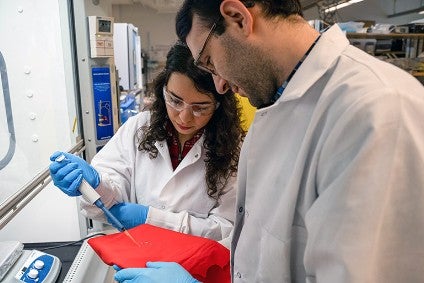

To solve the problem, Shabanian and the research team added a nanoscopic layer of silicone to each fibre in a woven fabric, creating an oil-repellent jacket fabric that repels water, sweat and oils.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataBy understanding how the textile weave and fibre roughness affect the liquid interactions, Shabanian says she was able to design a fabric finish that did not use any PFCs.

“The best part of the new design is that the fabric finish can be made from biodegradable materials and can be recyclable,” she says. “It addresses many of the issues related to PFC-based repellent products and remains highly suitable for the kind of technical apparel consumers and manufacturers are looking for.”

Glasper adds: “An oil- and water-repellent finish that doesn’t rely on PFCs is enormously important in the world of textiles and is something the whole outdoor apparel industry has been working on for years. Now that we have a proof-of-concept, we’ll look to expand its application to other DWR-treated textiles used in our products and to improve the durability of the treatment.

“Working to lessen material impacts on the environment is crucial for Arc’teryx to meet our goal of reducing our greenhouse gas emissions by 65% in intensity by 2030.”

Kevin Golovin, principal investigator of the Okanagan Polymer Engineering Research and Applications Lab where the research was conducted, says it is important because it opens up a new area of green textile manufacturing.

He explains that while the new technology has huge potential, there are still several more years of development and testing needed before people will see fabrics with this treatment in stores.

“Demonstrating oil repellency without the use of PFCs is a critical first step towards a truly sustainable fabric finish,” says Golovin. “And it’s something previously thought impossible.”

The research is funded through a grant from the Natural Sciences and Engineering Research Council of Canada (NSERC), with support from Arc’teryx Equipment Inc.