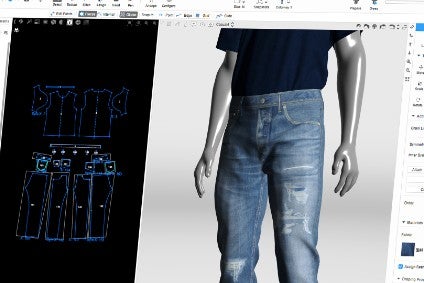

Hong Kong based manufacturing giant Crystal International Group has been scaling up its use of 3D virtual sampling, and expects to use the technology in 80% of the products that it develops by next year.

While many of its divisions – including denim and knits – were using the software before the coronavirus pandemic, the trend accelerated amid global Covid-19 lockdowns, travel curbs and social distancing measures.

Crystal International also says the technology has helped it to redesign the product development process, from digital design to the digital first sample stage.

Digitalisation of the sampling process also brings environmental and economic benefits to both buyers and manufacturers. It allows suppliers to produce new designs and styles digitally, speeds up sampling and lead-times, and reduces the number of physical iterations needed to go from concept to sale. The logistics time and cost of delivering the physical samples, as well as the production times, can be reduced as well.

Overall, the company estimates that product development cycles can be cut by half – shortening them to just three days. The use of a shared end-to-end online platform means all partners in the process – including customers and designers – can instantly review, comment and amend the prototypes.

In addition, digital sampling offers environmental benefits, since more than 75% of physical samples as well as associated materials, energy and water consumption can be reduced. Waste can be minimised by producing fewer manual samples.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“We started to adopt digital sampling technologies since 2017 and it has been gradually accepted by our customers. This demonstrates our sustainability commitment in redefining how we manufacture the jeans,” explains Miles Lam, assistant general manager of product development at Crystal Denim. “We envision that 80% of our self-developed products [will use] virtual samples in the product development stage by 2021.”

Danny Cheng, general manager of the knits division’s Technical Services Centre, adds: “Compared with the same period in 2019, it is astonishing that the number of digital samples rose 400% in the first half of 2020. We will strive to produce more in 2021 as we found that virtual sampling can save around 70% of cost for each sampling style and the response time of customers can be elevated by 75%.”

Looking ahead, Crystal International anticipates that virtual samples will eventually account for 90% of its self-developed products and is planning to create its own digital library for the product development process.

With around 20 production facilities spanning five countries – Vietnam, China, Cambodia, Bangladesh and Sri Lanka – Crystal Group makes lifestyle wear, denim, intimate, sweaters, and sportswear and outdoor apparel.

Earlier this year it became the first global manufacturer to team up with the Better Work initiative to help the programme scale up across the garment industry.

The company has also developed a Second Life closed loop denim line made from cutting room scraps that are recycled into high quality cotton fibre and new fabric. The denim is certified with Recycled Claim Standard (RCS), and can be categorised by material stream to provide full traceability for brands.

Crystal’s newly-released ‘Sustainability Report 2019’ explains how it has reduced its product carbon footprint by 44% since 2007. Under its ‘Third Global 5-year Sustainability Targets (2018-2022)’ it is working towards the goal of reducing carbon footprint per garment by a further 10% from 2017’s levels. Other areas of focus for the manufacturing giant include the circular economy and Industry 4.0.