Apparel software maker Gerber Technology has launched a dedicated task force to help manufacturers convert their production to produce personal protective equipment (PPE).

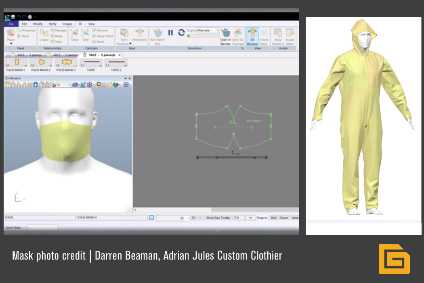

Based on a successful initiative in China, the Gerber PPE Task Force and Resource Team can offer advice, share best practices, support and technology to produce certain types of masks as well as protective apparel and accessories including raw material procurement and on-site support.

“In a global context where Covid-19 inexorably continues to spread, the global shortage of masks and other personal protective equipment needed to keep healthcare workers safe is a concern of everyone,” Gerber says.

More than 300 manufacturers rely on Gerber’s software, hardware solutions and expertise to produce masks and other PPE. Over the last few months, the firm has helped several customers transition to producing protective masks and other much needed medical supplies including Taglio Marchesini in Italy and Shanghai Challenge Textile Co.

“In what is an unprecedented global emergency, all of us in the manufacturing industry need to work together to protect those fighting Covid-19 on the front lines,” says Mohit Uberoi, CEO of Gerber Technology. “With over 50 years of expertise, we are doing our part and helping companies quickly transition into manufacturing PPE just as we did for our customers in China a few weeks ago and helped apparel companies successfully transition to manufacturing masks and other personal protective equipment.”

The Gerber PPE Resource Team is available to support PPE manufacturing including:

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData- Implementing pre-defined patterns and markers or defining fabric/sewing requirements

- Helping with the setup of cutter parameters specific to the selected fabrics

- Providing training, software, equipment and service technicians to ramp up production

- Changing over current production lines to the production of PPE

- Connecting supply and demand for PPE via our global ecosystem of customers and partners

- Introducing existing PPE manufacturers to those converting to PPE production

The launch comes as a number of industry players have taken steps to address increasing shortages in PPE due to the pandemic and constrained supply.

Swedish fashion retailer H&M Group is mobilising its supply chain to produce PPE to be delivered to hospitals and health care workers, while in the US, a coalition of apparel and textile firms has joined forces to build a supply chain to fast-track the manufacturing of medical face masks.

Elsewhere, chemicals manufacturer Huntsman Corporation is to begin making hydro alcoholic solution to produce hand sanitiser at its manufacturing site in Monthey, Switzerland, while Kering-owned luxury fashion labels Balenciaga and Yves Saint Laurent are preparing to manufacture surgical masks in their French workshops.

Most recently, sportswear giant Nike Inc said it is exploring designs for personal protective equipment to support doctors and nurses.