Despite a modest uptick in the production of apparel in the US, there are still obstacles to manufacturing domestically, a new report has found.

According to a white paper published by the US International Trade Commission, there is some evidence to suggest that reshoring has taken place in recent years in the country’s apparel sector, although on a modest scale. Among the reasons given for producing in the US are improved lead times, better quality control, and more flexible production.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

For the 2013-2016 period, capital expenditures were up 5% to US$301m. Although domestic shipments of apparel reached a record low of $11.5bn in 2014 and remained at that low level in 2015, they showed modest increases the following two years, reaching $12bn in 2016 and $12.5bn in 2017 – the first positive trend since 1998.

The American Apparel & Footwear Association (AAFA) estimates the domestic industry produced 603.8m garments in 2016, representing 2.8% of total apparel consumed in the US in 2016. This total was up from an all-time low of 2% in 2010.

However, any evidence of an uptick in the apparel sector is not reflected in employment data. Employment in the apparel sector steadily declined during 2013–17, down 21% from 145,000 workers in 2013 to 120,000 workers in 2017.

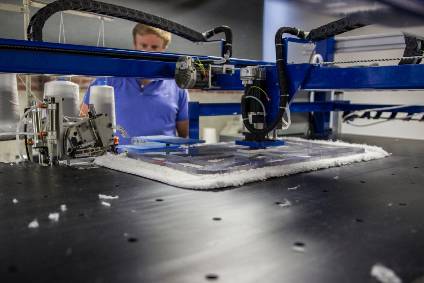

Indeed, the report points out that labour costs and availability are major concerns for those looking to manufacture in or source from the US. As a result, automation has become important throughout all stages of manufacturing – including designing, cutting, sewing, and moving the product during production process – to help improve production efficiency, minimise labour requirements, and reduce costs.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataFor example, the ‘Sewbot’ technology developed by Softwear Automation Inc. allows machines to replace much of the labour-intensive sewing process.

Tianyuan Garments Company is one company utilising this. The firm plans to open a $20m garment factory in Arkansas by the end of 2018. Its factory will use 330 machines from Georgia-based Softwear Automation, which combine fabric visualisation technology and robotics to control fabric during the sewing process. The factory will be capable of making 23m T-shirts per year at a cost of about $0.33 cents per shirt.

The industry is also adopting technology to accelerate the process of product development and to improve the fit of the final product. Li & Fung, for example, is using 3D virtual sampling and fitting to speed up the product development process from four to six weeks to four to six days.

“Increased demand for customisation and shorter lead times has made digitization and connectivity a critical tool to help speed the design, planning, production, and delivery of products,” the report explains. “Digitization and connectivity can improve the efficiencies within and between each stage of the product design and manufacturing process.”

In addition to actions taken by firms to improve their competitiveness, a number of local groups are helping to promote fashion design and clothing production in US. These can help smaller businesses to connect with the necessary resources for all parts of the production process, in addition to helping them attract clients, improve business processes, and develop talent to prepare local workforces with the skills required by the industry.

Despite the obstacles, the industry remains positive ‘Made in America’ is back. According to the Reshoring Initiative, apparel ranks sixth among industries that have reshored jobs since 2010. After years of decline, the domestic apparel sector has seen recent growth in both new investment and shipments.

“Both the textiles and apparel sectors point to innovation as a key part of their strategies for success,” the report says. “Innovation is vital for the development of new products, as well as for upgrading existing products, reducing costs, and improving flexibility in manufacturing operations.”

Click here to view the full report.