US fabric maker Polartec has developed a lightweight version of its sustainable Power Air fabric, taking the company a step closer to its goal of creating the world’s first fully recycled and biodegradable fleece, insulation fills and breathable waterproof fabrics.

Polartec launched Power Air in 2018 – a fabric that uses a construction technique that enables it to shed at least five times fewer microfibres than other premium fleece fabrics. This year, the company says it will go one step further and use a lightweight version that is made from one yarn, is fully recyclable and has a higher PCR content.

“Plastic microfibres are migrating into our oceans, being consumed by plankton and traveling up the food chain,” Polartex explains. “Scientists still don’t know the full consequences of this on human health but it’s a growing concern, so much so that in 2018 microbeads were banned from health products.”

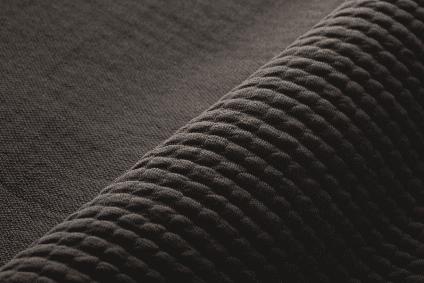

Polartec says it is addressing this problem on an ongoing basis. One of its projects has involved working with Swedish outdoor brand Houdini, to bring the first product made with lightweight Power Air to market in the Houdini Mono Air Houdi. Comprising 73% recycled plastic content, the fabric works by encapsulating air-trapping fibres – think bubble wrap – that results in an end product that is warm, comfortable and breathable yet sheds at least five times fewer microfibres when compared to other premium, mid-layer fabrics. In addition to its PCR content, the 100% polyester fabric is also fully recyclable.

Houdini will be launching the Mono Air Houdi at this year’s Winter ISPO and then to market on its website immediately after the trade show.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData