The Technip Energies-owned company, which focuses on textile-to-textile regeneration, plans to use this facility to transform post-consumer textiles into regenerated raw materials.

The planned plant will use Reju’s proprietary depolymerisation technology, converting textiles from French waste streams into rBHET, a material used in the production of new polyester known as Reju PET.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The project remains subject to a final investment decision by Technip Energies’ board.

The Regeneration Hub is expected to create 80 direct jobs and more than 300 indirect positions if it proceeds as planned. The project is designed to support France’s efforts in establishing a local circular industry and reducing carbon emissions.

Reju CEO Patrik Frisk said: “This French Regeneration Hub builds on our strategy to industrialise a circular post-consumer textile-to-textile model. By leveraging France’s ambitious circular-economy agenda and advancing our technology to new markets, we are reinforcing our mission to transform textile waste into valuable, circular resources.”

Reju is developing solutions to regenerate textile waste into new materials, responding to an estimated 121 million tonnes of textiles that are said to be discarded globally each year. Of this total, only 1% is recycled into new garments, while the rest is mostly sent to landfill or incinerated.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe company expects its French hub to establish scalable infrastructure for traceability and closed-loop fibre use across France and Europe.

This development aligns with other company initiatives such as Regeneration Hub Zero in Frankfurt, Germany, a planned site in Chemelot (Sittard-Geleen, Netherlands), and a recently announced US hub in Eastman Business Park, Rochester, New York.

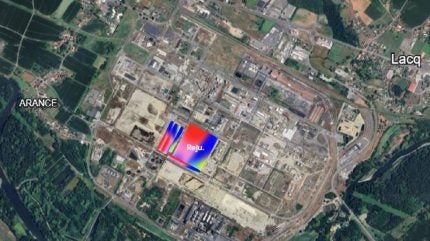

The Induslacq platform, where the new hub will be established, is owned by TotalEnergies.

Audrey Le-Bars, CEO of Chemparc, a development agency supported by the state, local authorities (Region Nouvelle-Aquitaine, Community Lacq-Orthez), and industry, has welcomed the selection of Lacq as the site for Reju’s first Regeneration Hub in France.

“This decision underscores the attractiveness of our industrial basin and illustrates the role of our Public Interest Group as a catalyst for this attractiveness,” Audrey Le-Bars said, adding, “This decision marks a new step in the development of a low-carbon circular economy. CHEMPARC is committed to continuing its support with diligence and energy for the success of this industrial project in the Lacq Basin.”

Reju uses technology co-developed with IBM Research to process textile waste into reusable materials.

The company also participates in organisations including ReHubs, Petcore, and Evolen, contributing towards building a traceable textile-to-textile ecosystem aligned with European standards.