The second of a two-part series, ‘Returns Management and the Customer Experience’, analyses responses from over 500 senior decision-makers from the apparel industry in the US and UK.

The report further discusses the growth of consumer returns, the impact on the wider industry, and how retailers can improve their returns operations and utilise return transactions to extend customer engagement.

In fact, it states, that a third (32%) of retailers agreed they spend too much time manually processing returned items, with 26% blaming a lack of staff for processing returns as a main cause. Additionally, 42% of returned items are sold at a discounted price, and 12% aren’t even re-sold.

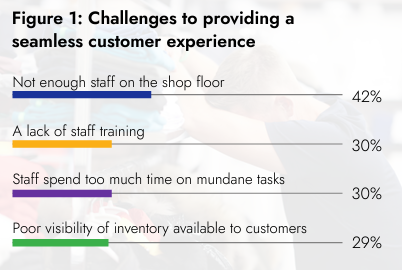

The report directs retailers to focus on delivering “streamlined returns processes” that reduce their own costs and improve overall efficiency. However, retailers struggle to deliver a seamless customer experience which is a result of the labour shortage and poor internal processes with 93% stating that technology is important in facilitating a seamless customer experience in-store.

Dean Frew, chief technology officer and senior vice president of RFID Solutions at SML Group, said: “Item-level RFID can play a pivotal role in alleviating the slow returns process on an operational level and manually processing returns. By investing in Item-level RFID technology, retailers can have instant visibility and access to reverse supply chains, enabling them to streamline back-end operations and send items back to the shop floor much quicker.

“It also significantly reduces time spent on manual inventory-related tasks enabling staff to aid customers and improve their experience. Investing in technology and processes that enable improved customer experience should be a top priority in an increasingly competitive landscape.”

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData