Puma ran a two-year-long RE:SUEDE experiment during which it piloted turning the experimental version of its classic suede sneaker into compost.

The brand said it produced 500 pairs of the experimental RE:SUEDE in 2021, which were made using Zeology tanned suede, a TPE outsole and hemp fibers. As the next step, these shoes were given to volunteers in Germany who wore them for six months to test their comfort and durability.

After the testing phase, Puma sent the RE:SUEDEs to a specifically equipped industrial composting area in the Netherlands operated by its partner, Ortessa Group.

According to Puma, a special procedure was required to convert the shoes into compost. The process involved shredding the shoes, mixing with green household waste, and placing it in a composting tunnel. They were then sprayed with leaching-water from earlier composting that contains nutrients and naturally heated due to the biological activity and controlled air circulation in the tunnel.

Puma explained that after approximately 3.5 months, the materials that were small enough (<10mm) to pass through a sieve were sold as Grade A compost for agricultural use, in compliance with the Netherlands’ standards.

While the remaining materials were returned to the composting tunnel until they too had broken down to the desired level (<10mm). Throughout this process, Puma noted that Ortessa Group adhered to all legal requirements for compost applicable at their facilities in the Netherlands.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataAs a result of the feedback received from the people who wore the RE:SUEDE for half a year, Puma said it will improve the comfort of future versions of the shoes by enhancing the overall fit by using a new material pattern for the upper and the sock liner.

Additionally, the brand mentioned transparency as another important pillar of the RE:SUEDE experiment, as Puma said it will share insights in a detailed report so its peers and other interested stakeholders can learn from the experiment and apply the learnings to their own initiatives.

Anne-Laure Descours, chief sourcing officer at Puma, said: “While the RE:SUEDE could not be processed under the standard operating procedures for industrial composting, the shoes did eventually turn into compost. We will continue to innovate with our partners to determine the infrastructure and technologies needed to make the process viable for a commercial version of the RE:SUEDE, including a takeback scheme, in 2024.”

RE:SUEDE experiment was the first programme, together with the polyester recycling programme RE:FIBRE, to launch as part of Puma’s Circular Lab.

Since 2017, the company has been able to reduce CO2 emissions from materials by 32%. However, Puma believes the overall CO2 emissions can be reduced by a further 7%, despite significant growth in sales.

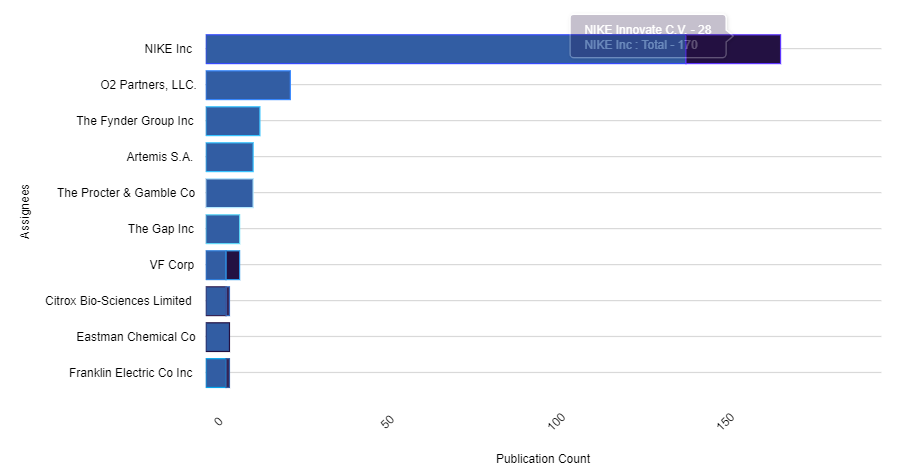

Sports brand leads patents for ‘biodegradable’ (November 2018 to November 2023)

Data shared by GlobalData shows that the American athletic footwear and apparel brand Nike is at the top of the charts for patents related to ‘biodegradable’ with a total of 170 publications. Followed by the shoe insole manufacturer O2 Partners LLC with total 25 publications.

This list also includes the conglomerate Artemis SA, Gap Inc and VF Corp.

The apparel industry is increasingly focusing on the use of materials that are sustainable and help make the industry more circular. Brands and retailers are either collaborating and investing in the development of eco-friendly fibres and materials or starting to think about the end-of-life of products.

These examples are proof that the fashion apparel industry is not far behind in keeping up with its words to make the industry more sustainable and circular.

Our signals coverage is powered by GlobalData’s Thematic Engine, which tags millions of data items across six alternative datasets — patents, jobs, deals, company filings, social media mentions and news — to themes, sectors and companies. These signals enhance our predictive capabilities, helping us to identify the most disruptive threats across each of the sectors we cover and the companies best placed to succeed.