We all know how poor purchasing practices impact on garment supply chains and their workers. Yet rather than getting better and things improving, they seem to be getting worse.

In the first wave of the pandemic last year, we saw brands refusing to pay for complete and in-progress orders, as well as extending their payment terms and demanding whopping discounts of up to 50 percent on completed orders.

These issues continue to rear their head more than 16 months later.

They are a global problem. They impact suppliers in Bangladesh, India, Pakistan, Cambodia and beyond. No supplier is safe, large or small.

It is a stark reality for suppliers that we remain so heavily dependent on the goodwill of brands when it comes to being paid for orders. There is no real legislation to protect us and too many brands have taken advantage of a relaxed regulatory environment in which the penalties for going back on contracts are essentially non-existent.

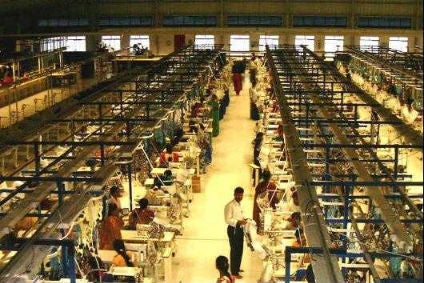

Poor purchasing practices hit those right at the bottom of the supply chain: garment workers. This is, of course, a huge irony given the industry talks regularly about corporate social responsibility and the importance of looking after garment workers.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIt is a fact that garment workers will continue to be exploited, to live with uncertainty and to experience times when they cannot put food on the table until we find a way to ensure a level playing field for brands and their suppliers.

I genuinely believed the pandemic might be the wake-up call our industry needs, and that the public pressure placed on brands that had reneged on contracts and walked away from completed orders might actually lead to change.

I was wrong. The most recent evidence suggests that unit prices for apparel continue to fall and suppliers are being squeezed as hard as ever. Many suppliers report having sold at or below cost simply to keep factories functioning. This is no way to run a business or, indeed, an industry.

Is change coming?

In recent months, the main trade bodies of leading textile hubs have established the Manufacturers Payment and Delivery Terms Initiative. This initiative has been started by the STAR Network – which is supported by GIZ FABRIC – and by the International Apparel Federation (IAF). It is also supported by the Better Buying Institute and the OECD and a range of experts and includes 13 participating manufacturing associations, including Bangladesh, Vietnam, Turkey and others.

The hope is to work together to look at ways to tackle purchasing practices.

The German Partnership for Sustainable Textiles has announced that in 2021, its annual topic will be purchasing practices. The industry body has acknowledged that responsible purchasing practices enable suppliers to plan their production and working hours effectively and to pay workers fairly. They also enable suppliers to invest in the overall improvement of working conditions and thereby strengthen resilience in the supply chain.

These initiatives are welcome, and it is important that purchasing practices are now receiving the spotlight they deserve.

However, after more than a decade of talking on this issue, and having had 12 months in particular where the relationship between brands and suppliers has been under the spotlight like never before, we are yet to see anything concrete put in place to tackle this. Nothing is set in stone or codified, there are no penalties for brands who renege on contracts.

Does anybody in our industry genuinely believe this issue can be changed from within? Does anybody think a collection of disparate initiatives can place enough pressure on buyers to pay their suppliers on time on agreed terms?

We have spent years expecting our industry to regulate itself, of saying the same things, but we are still no further forward.

Legal jargon

There is, of course, another way. The long-term solution for our industry is, I believe, something legally-binding that the whole industry signs up to. This would be an industry charter, a set of minimum agreed conditions around brand purchasing which all buyers and sellers must adhere to.

This charter would be just like the Bangladesh Accord and have an independent regulator and include signatories from brands, suppliers, industry bodies, and unions.

We all know the Bangladesh Accord achieved amazing results and we know why. It was because it had teeth. Brands knew there would be consequences if they failed to adhere to its guidelines on factory safety.

An industry charter on purchasing practices would be different as it would need to be global so that no one garment sourcing hub was placed at a competitive disadvantage or otherwise. This is a global problem which needs a global solution – and sooner rather than later.